By S. Prasanna, Murugappa Organo Water Solutions Private Limited

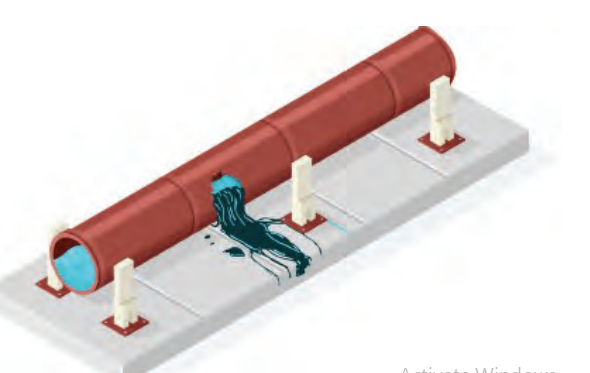

Water, a highly indispensable resource is depleting in a faster rate. Due to various reasons like population, pollution, undue wastage and so on, water resource gets exhausted rapidly. It is estimated that a person uses 200 litres of water per day. One can’t do without water but one can definitely make a spectacular change in treating the waste water. It’s not a must that agriculture needs fresh water, even treated water will work wonders; same is the case of industries which can manage with treated water to function. Water Treatment Plants and Sewage Treatment Plants are the keys to make this happen and one should never forget to make it environment friendly as this is the need of the hour. Water is a critical source of life on our planet; it plays paramount roles in agriculture, manufacturing, production of electricity, and to keep humanity healthy. Approximately one billion individuals around the globe are unable to access clean drinking water (Krchnak 2016). Urban water is regularly transmitted using underground pipelines. Water transmission pipelines periodically lose an average of 20% to 30% of the water transmitted through them, and those numbers can escalate above 50% in old systems especially ones that have suffered from inefficient maintenance. There are multiple causes for loss of water in transmission pipelines which include leakage, metering errors, public usage such as firefighting, and theft (Hunaidi 2000; El-Abbasy et al. 2016). The most critical route for losses is a leak, as they are considered to contribute an estimated of 70% of water loss in water transmission systems, this value is expected to become higher in undermanaged networks (Van Zyl and Clayton 2007). Proper management of solid and liquid wastes is an important determinant of improved sanitation in a country. The liquid waste poses serious threat of contaminating ground water. Management of waste water may focus on maximum reuse of waste for agriculture purpose with least operation and maintenance costs. People must be aware about 4R’s for effective waste management. Reduction, Reuse, Recycling and Recovery. Where there is awareness there will be optimal reduction in wastage. Eco-friendly technologies in water industries result in favourable positive result ensuring healthy and safe environment. Non – Revenue Water (NRW) is water that is pumped and then lost or unaccounted for. A World Bank study puts the global estimate of physical water losses at 32 billion cubic meters each year, half of which occurs in developing countries. Water utilities suffer from the huge financial costs of treating and pumping water only to see it leak back into the ground, and the lost revenues from water that could have otherwise been sold. If the water losses in developing countries could be halved, the saved water would be enough to supply around 90 million people. Non-revenue water (NRW) management allows utilities to expand and improve service, enhance financial performance, make cities more attractive, increase climate resilience and reduce energy consumption.In water constrained environment, NRW management often offers superior costeffectiveness compared to supply augmentation. At the same time, revenues from saved water improve a service providers’ bottom line whilst lower water abstraction increases city resilience. But the benefits that arise from reducing NRW are yet to become driving forces behind tackling this widespread challenge in developing countries. In one instance, a study was conducted in the United Kingdom to identify the impact of water leaks on an urban water network. On a yearly basis, the country is expected to dig 4 million holes into its road network for pipe installations and leak repairs. The monetary impact of the repairs is estimated to be at 7 billion £ (around 10 billion US$) annually. The overall cost can be divided into two main portions, 1.5 billion £ (around 2 billion US$) indirect damage costs and 5.5 billion £ (around 8 billion US$) in social impact costs. Another aspect of the dangers of leaks is their tendency to grow. The growth of leaks can allow the introduction of pathogens and contaminants from the surrounding environment into the network in the case of water networks and quite the opposite in the case of oil and gas networks which would result in dangerous impacts on human life. Why Nrw Reduction Still Receives Scant Attention? Reasons for utilities not making progress include weak capacity, lack of incentives, poor financial discipline and the effort required to find and fix leaks compared to building new treatment facilities. This has created a lethargy which is now being shaken by pressures coming from climate change, water scarcity and increasing expectations of consumers. As part of Stockholm World Water Week 2016, the World Bank, in partnership with the Inter-American Development Bank (IDB) and the International Water Association (IWA), hosted a workshop to explore the political, financial, technical and market constraints of this under-utilized, but impactful task. Using case studies, the workshop explored how constraints have been overcome and brainstormed with water experts about a global initiative on scaling up NRW management. The workshop and a more formal partnership with IWA was a part of a broader initiative within the World Bank Water Global Practice to help build sustainable urban utilities. This initiative was supported with funds from PPIAF and was focused on how to increase the use of Performance Based Contracting (PBC) as one way to address high levels of leakage. Through PBCs, utilities can access the capacity and equipment that they lack – and with payments based on results the incentives to perform are high and the risk of non-performance by the contractor is reduced. A World Bank financed project in Ho Chi Minh City used a NRW PBC approach in a part of the city and saved half of the water that was previously being lost to leakage – 100,000m3/day (enough water to serve 500,000 people). A truly remarkable achievement which set a new benchmark for the NRW PBC model. With the proof of concept now a given, the challenge is how to streamline and simplify the NRW PBC project preparation and contracting process. The World Bank and IWA are working together in collaboration with the IDB to advocate for the reduction of NRW and create more dynamic markets at national and international levels. The losses and damages created by leaks requires novel techniques and approaches to minimize their negative impact and deal with them as fast as possible. As a result, multiple researchers dedicated their efforts for the development of a vast variety of techniques for leak detection and leak location. Defining Leak Detection In 2009, Hamilton defined leak detection as a subsidiary of three main phases known as localize, locate, and pinpoint or LLP. Localize is defined as narrowing down a leak to a specific segment within the network or a specific district metered area after the suspicion of a leak. Several tools can be used in this domain such as district metered area and fitting surveys. The second phase is locating, and it is the first phase where a location for the leak is determined. According to Hamilton, the location of the leak is said to be within a radius of 30 cm. Furthermore, multiple tools are available for utility in this phase including correlators and microelectromechanical. Finally, the third phase, according to Hamilton, would be pinpointing. Pinpointing is another phase where another estimate for the exact location of the leak is determined but within a radius of 20 cm. In this phase, a variety of tools are available including hydrophones and geophones. The difference provided by Hamilton between locating and pinpointing is a 10 cm-difference in radius, which is negligible and offers no actual differentiation between the processes or the actual outcome of each phase. Therefore, it is more efficient to merge the two phases due to similarity. In contrast, multiple researchers in the field of leak detection have highlighted the existence of another challenging aspect in the development of leak detection systems and approaches. The challenge lies in differentiating the signs of leaks from other aspects such as pumps or an open hydrant. This problem is vivid in acoustic noise loggers and accelerometers and other wireless sensor devices that are used in leak detection. Sensors would pick up any form of signs and signals similar to those of leaks and end up providing false alarms. False alarms create an expenditure of workforce and funds for the bodies monitoring the respective networks. Therefore, a new phase of leak detection is proposed, and that is the identification phase. Process In Leak Detection Water is lost through leaks and cracks in pipes and their fit tings. Since most infrastructure is underground, it is virtually impossible to visually determine the location of these leaks unless the water has reached the surface (causing ponding and sink holes, structural damage, buckling pavement, etc.), and the exact location may be indeterminate. Leak detection requires special technologies that allow inspectors to precisely determine the location and severity of pipeline leaks. This is a field that continues to grow and advance by utilizing both established technology and by adopting emerging methods.The advances in leak detection research have grown remarkably in recent years, but the field of leak detection is not a new field of research. The damages created by leaks in pipeline networks presented researches with the curiosity of developing reliable and immediate solutions to fight the leakage epidemic. Acoustic detection remains the primary means of detecting and locating pipeline leaks. The method of acoustic leak detection is described as “the systematic method of using listening equipment to survey the distribution system, identify leak sounds, and pinpoint the exact locations of hidden underground leaks.” Water escaping under high pressure from a pipe leak or crack makes a distinct rushing or hissing sound that can carry considerable distance along the length of the pipe itself (in contrast, the loose soil surrounding the pipe in its backfilled trench makes a poor conductor of sound). In this sense, the pipe acts as a medium for transmitting sound. In doing so, it can act like the strings on a guitar, vibrating with different pitches for different pipe lengths, diameters, and materials. Small diameter metal pipes carry sound the greatest distance, up to 1,000 linear feet, while large diameter polyvinyl chloride (PVC) pipes can carry sound only 100 feet. The listening devices used to detect this sound come in various operational modes. They can be mobile or fixed, direct or indirect, external or internal, or transit data via radio or utilize manual download into laptop computers. There are mobile acoustic sensors that are manually operated or run along the pipe segment on wheels. In either case, the sensors consist of ground microphones that listen below the surface as the operator walks along the pipe segment. As he operates his sensor, the signal will get louder as he zeroes in on its location. Secondary leak detection methods utilize pressure differences. These are measured by strategically located flow meters and pressure gauges that can, by differences in the readings, bracket the location of the leak. Pressure drops compared to initial operating condition immediately after installation will indicate the escape of water and subsequent lowering of pressure from its original state. The two systems can be used together with the pressure and flow differentials used to bracket the leak’s location and mobile acoustic sensors running along this bracketed length to pinpoint its location. The use of the former saves considerable time and tedious effort by the latter. Leak Audit Procedures Leak detection is just the first step. To minimize leakage loss, a water supply system must have a program of continuous audits, of which leak detection is just a part. A full-scale audit program should be performed at least annually with complete analysis of the leak data—not just for the current audit, but accumulated data records over time. A proper audit examines the accuracy and completeness of the system’s entire leakage database. This data does not just include reading on the leaks themselves, but also indirect measurements of potential leaks such as customer billing and receipts, along with flow meter and pressure gauge readings. Pressure readings can be used to create pseudohydrostatic contours representing areas of low and high pressure. Low pressure zones thus revealed are another danger sign that a leak may be occurring in these areas. Audits are typically priced by the mile, and they are not cheap (especially for large water supply systems). But they are essential and are far less expensive than continued water loss. Audits provide update information on system performance, tagging what is failing and (more importantly) highlighting those areas that are functioning properly. This is important with regard to evaluating previous maintenance and repair operations prompted by the results of previous audits. In short, a water system audit provides its own information feedback loop. As a side benefit to the audits, complete inventories of the water system’s equipment, valves, and fittings can be collated. The next step is to identify all potential sources of water feeding into the water supply system and sum up their measured flow rates (gallons per day). This gives the baseline value for the amount of water that should be flowing through the system and through each pipeline network subsection. Next, flow meter readings should be tallied up. This provides hard field data (adjusted for potential meter error) on actual water usage flow rates. Then water flows entering the system can be compared with water usage exiting the system to determine the gross magnitude of water leakage. After this amount is determined, the audit can break down water usage by individual customers (residents, businesses, commercial and industrial facilities, rental units, etc.). This involves both a thorough review of the data from the last year’s audit and the meter readings over the past year. Increases in flow rates indicate that the customer has either increased its usage due to expanded operations and increased economic activity, or that the customer itself has unreported leaks. If the latter is the case, it is up to the customer to find and repair any leaks that are occurring on his side of the flow meter. The water utility is only responsible for leaks on the street side of the meter. With each pipe segment of the water distribution system defined by flow and pressure monitoring points, both the approximate location and amount of water being lost at a leak can be determined. The manual detection can then proceed to find the precise location of the water loss. The kind of leaks can vary considerably and can include illegal water taps, broken and malfunctioning meters, leaking pipe fittings and fixtures, and worn out valves. In addition to pipeline leaks, leaks can occur in water storage structures such as water towers, storage tanks, and reservoirs. Emerging Leak Detection Technologies—Inside And Outside Detecting leaks within a customer’s facility is not so much a matter of visibility, but of vigilance and continuous monitoring. New technologies are emerging that allow customers to pinpoint leaks within their facilities with a higher degree of accuracy than the traditional methods of water leak detection such as spot detectors, which detect leaks at a single point (such as a curbed area under a piece of equipment). Though economical and easy to use, spot detectors can only detect accumulated water in contained or low points. Water that doesn’t touch the spot detector’s probes will not be detected. An improvement on this system utilizes non-conductive sensing wire (which avoids shorting out if it comes into contact with metal surface or projections) and can detect any fluid, not just water. Intelligent cable sensors are just one area of technological development. Each new advance will have to be rigorously evaluated for general usefulness and specific applicability. The factors used to evaluate new technology include: breadth of application and how many uses it can be applied to; ability to adjust sensitivity to different liquid amounts; the ability to quickly reset its readings and re-establish its sensing operations; ease of installation; scalability and adjustment to future expansions; and ease of integration into the existing control and monitoring system. Future technological advances must pass all of these hurdles to find acceptance among both customers and utilities. Water Signal measures water flow in real time, allowing for fast detection of leaks and water conservation. The system allows Portfolio managers to login with any internet-accessible device and see a centralized dashboard of current water consumption across all sections of the water supply system. Its unique hourly and daily alert levels warn managers about excessive losses and prevent subsequent high billings. This real-time water use reading is far more efficient than standard monthly meter readings. The Water Signal technology is directly installed on a water meter and then proceeds to manually calibrate the device to ensure accuracy. Data is then acquired continuously in real time and uploaded to a secure data center. The accumulated water use data is available to operators 24/7 through any internet device (iPhone, iPad, laptop, etc.). A sudden spike in water flow, indicating a catastrophic leak, will result in alerts being sent to the operators via email and SMS text message. The alert will include specific data indicating which water line has broken and how much water has been lost. This system has been used successfully in a number of commercial and public applications. Conclusion: The Advancement in Science and Technology have resulted in abundant water leakage detection and monitoring systems but it all works fine only with the potential involvement of people. She/ he is the mastermind to help detect, resolve the water leakage and install devices to restrain the leakage or stop the precious water from getting wasted. This shouldn’t be the last resort but taken into careful consideration when planning a water pipeline. The immediacy of action lies totally on human, they must realise the importance and arrest the leak at once to make the best use of water resource. AUTOBIOGRAPHY I was born into a warm and loving family. My father Sankar G is an Industrialist handling fabrication job, and my mother Malarvizhi T was teacher at a Government High School. We were in a conservative family those days, and my parents worked hard to make sure we had an exciting childhood. As many Indians, I hold an Engineering degree in Biotechnology and due to my aspiration for nature I pursued my master’s in environmental science and technology so that I thought I can contribute towards sustainable living for the future. Water scarcity was a bigger problem at my place and hence, I always have a concern on saving water for the future. Without doubt or second opinion, I wanted to have a job in the field of water treatment and as per my aspiration I started working as Process and Proposal engineer at L & T construction handling mega projects like 2 MLD STP at Rashtrapathi Bhavan, Delhi, SMART city projects like DHOLERA, Gujarat. I joined Murugappa group in 2018 as Deputy Manager handling Marketing, Process and Proposal and heading a team of ten. We provide customized, end to end solutions for complex Industrial effluents, design and execute projects and products, which is done by few companies. I hope that I have contributed a little to preserve our nature and strongly believe that positivity, smart work and optimistic approach leads to success always.