By Dr. Jagjit Singh Sehra, President, CST Associates

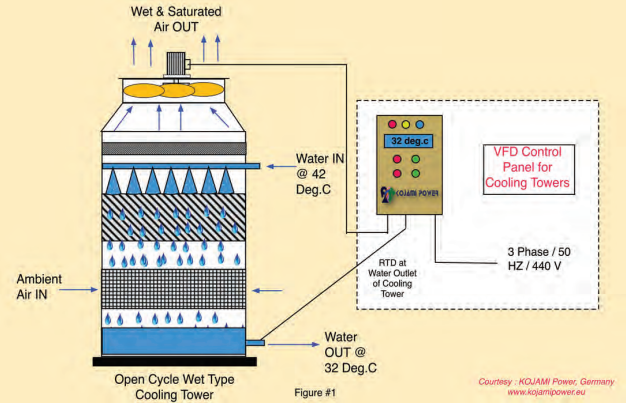

Today we find new challenge of water that is being used in the cooling tower. In my pervious article we have discussed how power industry evaporates nearly 2900 liters of water while producing 1 Mega Watt of power. Since the alternative methods of using Adiabatic Cooling towers have been discussed in my pervious articles, which require huge investments. Right now, industry all over the world is passing through the time times because of Corona. Currently companies are very much scared to go in for the huge investments. But on the other hand, we have great challenge of environment which needs to be taken care to avoid further damage to our ‘Great Mother Earth’. At this movement need on an hour is to provide a solution to the power industry & air conditioning industry that can save great amount of water by adding certain or modifying their cooling tower. Controlling the Fan Speed Most of the contractor companies while doing bidding don’t consider installing the VFD on their cooling towers. There can be any reasons for the same. One the reason is the cost. But they forget how much harm they are doing to the environment by not doing so. We are already losing billions of liters of water in the cooling tower because of this worldwide. This needs to be control immediately & governments should bring this as a mandatory law in order to save the environment. This will ultimately help everyone. As discussed in my earlier articles as the world population increased the required for the power and air conditioning also increased which resulted into more and more waste of water because of open cycle cooling towers. If this water is saved millions of people can take benefit from the save. Let us understand the concept by taking an example of the power plant first and then for the air conditioning. Water Saving in the Open Cycle Cooling Towers used in the Power Plants In the thermal power plant maintaining vacuum is very important for the steam to follow smoothly. Normally the cooling towers are designed maintaining the water outlet temperature (from cooling tower) as 32 Deg.C & return temperature of 42 Deg.C. This is the design condition which is required even at the extreme ambient air condition. Since the cooling tower water is directly cooled by using the ambient air, therefore we must have a device which reads the ambient temperature and adjust the requirements as per the ambient temperature. Different zones on our plants have different air temperature profiles. Also, the air temperature keeps on changing every hour. For example, in the extreme summer we may touch a temperature (DB) of 50 Deg.C in the day time, but on the same night the temperature (DB) can become as low as 30 Deg.C. In this case if the cooling tower do not adjust to the new temperature, then there is a great wastage of water. Since the cooling towers are selected and design considering the maximum ambient air wet bulb temperature & on the concept of A.

Which is Water outlet minus the Wet bulb in temperature. Lower the A, higher will be the size of the cooling tower & higher the A, lower will be the size of cooling tower. Another factor of the selecting the cooling tower is LG ratio. Which is maintained as 1.5 in most the cases. Now if the fan speed is fixed all the time, then we will have problem of water being over cooled in the lower ambient temperature and becoming hot over the higher temperature. So, at this point if we have a VFD (Variable Frequency Drive ) in between the Fan & the supply then the fan speed will keep on changing with the variation of the ambient temperature. Coming back to our our example we require 32 Deg.C at all the times. When ambient temperature goes higher then let us say 50 Deg.C DB & 27 Deg.C WB the fans will run at the full speed. As the ambient temperature comes lower and lower than the fan seed will come down gradually. A temperature range of 32 Deg.C will be maintained all the time. This can be clearly seen from the above Figure #1. This kind of VDF Pannel boxes is not readily available in the market. After doing research it was found a very few companies like Kojami Power, Germany offers such kind of product. This can be brought in India through their agents. For more details on the company, you can visit their website as www.kojamipower.eu. The readers can also explore few more sites. How Does the System Works? The panel consists of three major components, One is the VFD, which varies the fan speed as per the linear approach, second is the PLC which is connected to the third component called RTD. The RTD reads the outlet water temperature of the cooling tower. This feeds the signal to the PLC, which sends the signals to the VFD to adjust the speed by adjusting different frequencies. We can set the water outlet temperature present on the HMI screen. The system when starts read the water outlet temperature, suppose we set it as 32 Deg.C & PLC reads that this is 38 Deg.C. The speed of the fan will automatically increase this bringing the temperature at 32 Deg.C. Once the temperature is achieved then the fan will run a constant speed to match the water outlet temperature. In the similar fashion if the temperature at the outlet is lower than the fan speed gets slow till the set value is achieved. This is so simple and easy to use. Benefits of this system: 8 Saving of Water: Since the cooling towers are designed at the optimum capacity, which is for few days in a year. So, reducing the fan speed means that we are also controlling the blow down loses. Which is a direct saving. 8 Saving of Power: We also save on the power as the motor current drawn decreases. Thus, power required to run the cooling tower is decreased. Which is a direct power benefit in terms of revenue. Like they say penny saving is penny entered. 8 Savings on the life cycle of components: When the motors and fans are not running at the full speed at that point the life of the moving component is also increased thus saving on the regular replacement cost. 8 Maintenace Cost: Since the cooling tower will not be operating at 100% designed capacity it also decreases the scale formation in the tower. Which in turns saves great amount of cost that incurred on chemicals and man power. How much quantity of water can be saved ? This is a very broad question it is not easy to work out how much water will be saved. But these can very easily be calculated on the case-tocase basis. While calculating the water quantity to be saved, we need to consider the following parameters. 8 Weather it is a new cooling tower or a retrofit? 8 What is the temperature profile for the 8760 hours in a year? 8 What the cost of water & power in the area? 8 Application where cooling tower is installed. 8 Size of the cooling tower in terms of the capacity. These are the few parameters that need to be studied while working on the project. An advice to the Pollution Board or Ministry of JAL Shakti in India Large Buildings As we are facing the water problem in almost all every city, where large building is run the air conditioning systems with the water-cooled chillers or VAM’s. It is advice to make this product mandatory so that the Hugh amount of water can be saved. Industries Industries that use the open cycle cooling towers to cool the machines, should be also advised to install these units so that the water usage can also come down. This will further help to maintain the water level on a large way. Power Plants Power industry which depends so much on water and also consumes great amount to water should also be advised use this product as mandatory so that we can run the plants efficiently. It will also give benefits to the power plants as the power that they save from cooling towers can be sold to the consumers thus bringing extra revenue. Next Article In the next article we will give some light on how we can convert the sewage water that we can use for the cooling towers.