ProjectWise Component Center Helps Facilitate Repeatable Workflows to Save More Than GBP 3.7 Million Supporting Environmental Sustainability.

Meeting stringent requirements for phosphorous removal

The United Kingdom water industry’s Asset Management Plan 7 (AMP 7) includes a heightened priority for improving water quality schemes. In particular, it focused on reducing the amount of phosphorous released into watercourses, which are natural or artificial channels where water flows. Originating from a range of sources, including wastewater discharge and water main leakages, high levels of phosphorous yields extensive algae growth, posing a significant threat to watercourse habitats and environmental sustainability. To meet the U.K.’s new stringent requirements for the removal of phosphorous at wastewater treatment plants, many water companies needed to upgrade their existing assets. Mott MacDonald Bentley, a joint venture between JN Bentley and Mott MacDonald, identified an opportunity to initiate a waste treatment phosphorus removal program for their U.K. water company clients.

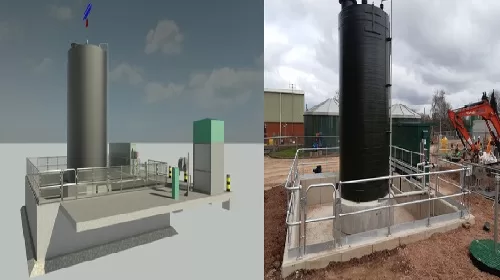

Known as P schemes, the phosphorus removal program consisted of more than 100 projects across their seven client frameworks with a total design and build budget of GBP 300 million. “This large program created an opportunity to increase efficiency with a standardized approach across projects, reusing designs and data across different locations and clients,” said Anmol Khurana, product lead for Moata Intelligent Content at Mott MacDonald Bentley. The successful completion of the P schemes will reduce the amount of phosphorous that ends up in the waterways, significantly improving water quality, the environment, and sustainability. It will protect habitats and ecosystems while increasing the amount of available drinking water.

Repeatability, standardization, and collaboration

For such a large program like the P schemes, having a standardized delivery approach and being able to make decisions at a program level is far more efficient than the traditional delivery methods of individual designers creating components in silos. “The vision was to make the design and delivery process for all the projects as efficient as possible by developing standard solutions,” said Khurana. However, the sheer scale of the project presented data sharing and coordination challenges, compounded by the unique needs of each client, making standardization difficult. At the heart of Mott MacDonald Bentley’s approach was breaking down the design and delivery process and implement repeatable solutions, data standards, and collaboration in design, procurement, and construction.

“Traditionally, designers needed to recreate components and data spreadsheets for each project,” said Khurana. Recognizing that this method was neither cost, resource, nor time efficient, Mott MacDonald Bentley sought to identify reusable components across their client frameworks and create standard parametric models in a connected digital environment to foster cross-framework collaboration. To achieve this goal and deliver more value with fewer resources, they realized that they needed an integrated digital technology solution capable of intelligent modelling to develop a component library, standardizing design and delivery for all removal schemes across multiple client frameworks.

An integrated intelligent technology solution

Mott MacDonald Bentley identified their industry leading BIM library, Moata Intelligent Content, powered by Bentley’s ProjectWise, as the digital solution to collect standard components from their supply chain and produce a standardized parametric model that was made available across their client framework. “ProjectWise provided agnostic file hosting, an intuitive search feature, and rapid access functionality that powered Moata Intelligent Content and allowed users to access data quickly and produce a standardized parametric model that could be linked with standard or templated documentation available to all client frameworks,” said Khurana. The integrated intelligent technology approach promoted repeatability, standardization, and collaboration, providing a strategic solution to enable consistent, quality, and efficient design.

Through easy-to-use access to a vast managed library of specially created, standardized, and compliant parametric digital assets, Moata Intelligent Content allowed users to incorporate data-rich components into their design models. Combined with Bentley’s collaborative digital technology, the platform facilitated reuse of content from a managed central repository with parametric functionality that allowed for component dimensions and types to be adjusted to suit each client’s requirements, eliminating the need for designers to recreate components and data spreadsheets. “The content library currently contains 41 separate components and six assemblies, which are fully parametric,” said Khurana. The digital library and innovative use of ProjectWise standardized P schemes for 100 projects across Mott MacDonald Bentley’s seven water clients.

Delivering more with less

The use of Moata Intelligent Content on Bentley’s ProjectWise helped significantly improve efficiencies on the program. “Deploying ProjectWise for our removal projects has proven to be instrumental in achieving substantial gains in both design efficiency and waste reduction across our entire project portfolio,” said Matthew Dinsdale, DfMA digital lead at Mott MacDonald Bentley. The establishment of a unified central repository effectively mitigated the complexities arising from outdated component designs, as well as provided an environment conducive to improved collaboration. By leveraging rapid access to design resources and assemblies stored in the central component library, Mott MacDonald Bentley implemented more efficient design and delivery processes, accelerating the progress of P schemes, resulting in faster project completion, increased efficiency, and lower associated costs.

Working in a collaborative digital platform with parametric functionality streamlined workflows and facilitated repeatable design and construction, saving 13,600 hours and more than GBP 3.7 million in total costs, including an impressive GBP 632,800 savings through the reuse of standardized design components alone. “These savings mean that Mott MacDonald Bentley can deliver more P schemes with less resource, benefiting not only Mott MacDonald Bentley, but also its clients, the environment, and local communities, as the health of more U.K. watercourses is improved faster,” said Khurana. With the whole water sector facing affordability issues and a lack of resources, Mott MacDonald Bentley not only demonstrated cost savings and a return on investment, but they also helped to reduce the industry’s resource capability gap.

ROI

• The platform’s parametric functionality standardized design, reducing time spent on repeatable tasks to save 13,600 hours in design time.

• Mott MacDonald Bentley’s integrated digital solution improved program efficiencies, saving GBP 1.07 million.

Callout quote:

“Bentley technology was used to meet the unique engineering challenges of this program by providing a platform for a component library that was used to standardize design and delivery across more than 100 projects.” – Anmol Khurana, Product Lead for Moata Intelligent Content, Mott MacDonald Bentley.

Project summary

Organization:

Mott MacDonald Bentley Solution: Enterprise Engineering Location: United Kingdom

Project Objectives:

• To upgrade water infrastructure assets to meet new U.K. guidelines for reducing phosphorous.

• To standardize phosphorous removal schemes across seven water companies.

Project playbook:

Project Wise

Fast Facts:

• Mott MacDonald Bentley’s waste treatment P schemes consist of more than 100 projects across seven client frameworks.

• The large-scale program created an opportunity for Mott MacDonald Bentley to standardize workflows.

• Moata Intelligent Content, powered by ProjectWise, provided an intelligent digital platform to facilitate repeatability, collaboration, and standardization.