From the past few years, the significance of ultrafiltration membrane technology in wastewater treatment has grown a lot. It is universal and is able to produce high-quality treated water, making it a key component in modern wastewater treatment processes. However, due to various factors there are concerns that must be taken into consideration before incorporating it into the wastewater treatment.

In this article, we will explore the importance of UF membrane technology, address the cost concerns, and introduce innovative solutions to enhance the longevity of this membrane technology.

Let’s first dive deeper into the technology!

Benefits of Ultrafiltration Membrane Technology in Wastewater Treatment

Efficient removal of impurities:

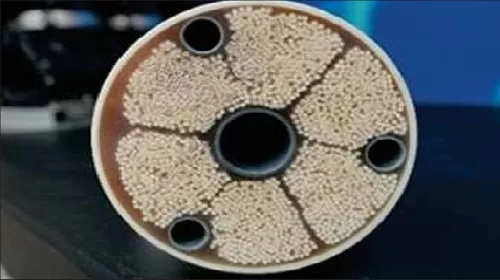

UF membrane technology is a game-changer in wastewater treatment due to its ability to efficiently filter out suspended solids, bacteria, and even some viruses.

• Compact Design: UF membrane systems are known for their compact design, making them suitable for both large-scale treatment plants and smaller installations. Their small footprint reduces the space required for treatment facilities.

• Flexibility: UF technology is versatile and can be applied in various wastewater treatment scenarios, including the removal of contaminants from sewage, industrial effluents, and stormwater. It can also be used in water reuse and desalination processes.

• Environmentally Friendly: The use of UF membranes contributes to a sustainable environment by reducing the discharge of pollutants into natural water bodies. It helps protect aquatic ecosystems and supports the conservation of freshwater resources.

These were some of the few importance or benefits of the Ultrafiltration Membrane Technology in Wastewater Treatment. Let’s now understand the cost structure and see how we can make the right decisions.

Implementation of ultrafiltration membrane technology can be quite expensive.

While UF membrane technology offers a lot of benefits as we have discussed before, the high initial cost of these membranes sometimes becomes a barrier in adopting the technology by a lot of outlets. For example, a 10,000 litres per day (10KLD) Sewage Treatment Plant (STP) would require a UF membrane plant worth Rs 2,00,000. However, it is essential to consider the long-term advantages and other good adaptations that will boost the wastewater treatment for your plant.

One of the major reasons for its highest costs is membrane fouling which is a common issue in UF systems, which requires additional investments in anti-fouling measures, cleaning, and replacement. Fouling should be prevented properly to avoid extra money on replacements for UF membranes.

Membrane fouling and clogging leads to the damage of UF membranes!

Let’s imagine a water filter in your home. The filter is like a super-thin sheet with tiny holes. It cleans water by letting water pass through these holes and blocking out dirt and impurities.

Now, think of this filter getting dirty because of all the stuff it has caught from the water. This dirt and slime stick to the filter and make it harder for water to go through. This is what we call “fouling.”

Similarly, membrane fouling happens when dissolved particles in the feed water collect on the surface of the UF membrane. These particles can include organic matter, bacteria, algae, minerals, and other contaminants present in the wastewater. When these substances come into contact with the membrane, they stick to its surface.

Here are some of the common reasons why membrane fouling can happen in your plant:

• Increased Operating Pressure: To maintain the desired flow rate and water quality, the UF system must compensate for the reduced permeability caused by fouling. This often necessitates an increase in the operating pressure, which places additional stress on the UF membrane and the entire system.

• Reduced Permeability: The presence of biofilms and trapped particles in the membrane can reduce the effective pore size and permeability of the UF membrane. This reduction in permeability can lead to decreased filtration efficiency and an increase in the membrane pressure needed to get the wanted flow rate.

• Microbial Growth: Nitrogen and phosphorus are essential nutrients for microorganisms, including bacteria and algae. When these nutrients are present in sufficient quantities in water sources, they can promote the growth of these microorganisms. As microorganisms begin to increase, they can form biofilms on the surface of UF membranes.

This biofilm acts like a blockage on the filter. It can slow down the water from passing through, like a traffic jam on a road. That’s why it’s a problem when too much food (nitrogen and phosphorus) is in the water because it makes these slimy biofilms, which can clog up the filter.

High-performance microbial formulations to the rescue!

Here’s how high-performance microbial formulations can address these challenges and avoid the membrane fouling to maintain the clarity of water and its desired flow:

1.Enhancing Biodegradation These formulations promote the growth and activity of aerobic bacteria, which are more efficient at breaking down organic pollutants.

• Enhanced biodegradation of organic matter leads to a reduction in BOD and COD levels and TSS, making the water cleaner and less prone to fouling UF membranes.

2.Nutrient Removal These formulations include compounds that facilitate the removal of nutrients like nitrogen and phosphorus. They can encourage the formation of insoluble compounds with these nutrients, making them easier to remove from the water.

• For example, they might help convert ammonia (a form of nitrogen) into solid particles or facilitate the precipitation of phosphorus compounds. Removing these nutrients before the water reaches the UF membranes reduces the chances of membrane fouling caused by nutrient accumulation and biofilm formation.

By improving biodegradation, removing nutrients, and eliminating odors, these formulations can help maintain a more efficient and trouble-free wastewater treatment process. This, in turn, reduces the risk of membrane fouling in systems like ETPs, STPs, and other treatment processes. Consequently, this can lead to reduced TSS in the effluent, which can significantly extend the lifespan of UF membranes, making your water treatment system more efficient and cost-effective.

Real-world example: Reviving a textile mill’s UF membrane

A textile mill’s wastewater treatment plant was initially commissioned using traditional methods, relying on cow dung, urea, and DAP (Diammonium Phosphate) for bioculture development. However, this approach resulted in a weak biological floc in the aeration tank. This underperforming system was susceptible to frequent shock loads that disrupted the outlet water quality. As a consequence, the UF membrane had to handle the entire load of high TSS and BOD.

While the UF membrane was able to produce clear water within acceptable parameters, it was filtering well beyond its designed capacity. This resulted in the membrane becoming clogged within a year of operation.

The challenges:

The textile mill’s wastewater treatment process faced several key challenges:

• Ineffective Traditional Approach: The use of cow dung, urea, and DAP did not create a strong biological environment, leading to inconsistent treatment and frequent shock loads.

• UF Membrane Overload: The UF membrane was pushed beyond its design capacity due to high TSS and BOD levels, resulting in clogging.

• Quality Control: The mill struggled to maintain consistent water quality, making it difficult to meet regulatory and environmental standards.

The solution:

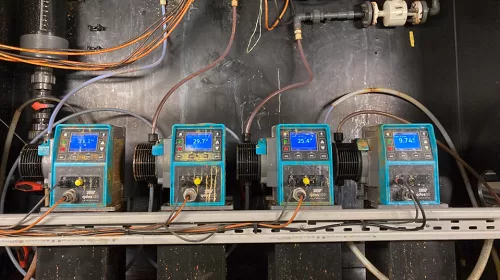

Our team introduced a comprehensive solution that included high-performance microbial formulations.

• These formulations were designed to enhance the biological treatment process and improve water quality.

• By utilizing these formulations, the UF membrane could be bypassed, allowing the microbes to break down pollutants, remove nutrients, and eliminate odors.

• Additionally, the team provided operational guidance to the treatment plant operators.

The outcome:

Our expertise led to the following positive outcomes:

• Enhanced Wastewater Treatment: The textile mill’s treatment plant achieved a more robust and effective biological treatment process.

• Lowered Membrane Load: The UF membrane was no longer overloaded, extending its lifespan and reducing the need for frequent replacements.

• Consistent Water Quality: The mill consistently produced high-quality treated water that met regulatory and environmental standards.

• Management Appreciation: The textile mill’s management acknowledged the effectiveness of the high-performance microbial formulations and the value they brought to the wastewater treatment process.

This case study highlights the significant impact that modern microbial solutions can have on industrial wastewater treatment. By adopting these technologies, we can solve environmental issues and ensure sustainable industrial operations.