As populations surge and industries expand, the demand for clean water is reaching unprecedented levels. However, the conventional approach in the industry, relying on single-use ion exchange resins, carries a substantial environmental cost. In the current linear model, significant quantities of virgin resources are consumed, greenhouse gases are emitted, and landfills bear the weight of discarded resins. However, with resin regeneration, there is potential for a more sustainable way forward.

Resins revitalized – a greener horizon

Resin regeneration is the process of rejuvenating exhausted water treatment resins, extending their lifespan, and optimizing their efficiency.

By renewing depleted resins, raw material usage can be minimized and the need to mine and process vast quantities of virgin materials to produce new resins becomes obsolete. The practice of regeneration allows for the reuse of existing resins multiple times, thereby significantly reducing the environmental footprint associated with resin production.

Furthermore, the process of producing virgin resins is recognized as an energy-intensive endeavor, emitting harmful greenhouse gases into the atmosphere, as compared to the regeneration process. This approach aligns with industry standards as a sustainable practice with lower energy demand.

Additionally, replacing exhausted resins traditionally is a water-intensive process in comparison to the resin regeneration process. This proves to be a practical business approach and helps to alleviate stress on precious water resources, aligning with broader environmental conservation goals.

But while the environmental benefits are undeniable, regenerated resins are not just a stopgap solution; they represent a paradigm shift towards sustainable water treatment practices.

The regeneration process

Akin to alchemy, resin regeneration involves transforming spent resins back into their prime by treating exhausted resins with specific solutions to remove contaminants and restore their exchange capacity.

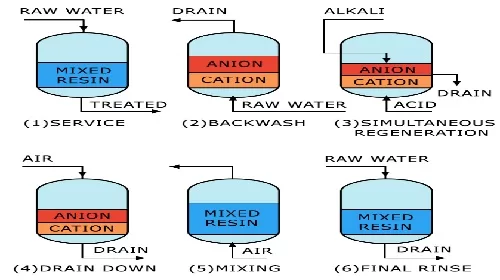

While the exact process varies depending on resin type and application, it typically entails:

1. Backwashing: Removing loose contaminants and preparing the resin bed.

2. Chemical regeneration: Applying tailored solutions to desorb captured impurities.

3. Neutralization: Restoring the resin’s pH balance for optimal performance.

4. Rinsing: Removing residual chemicals and ensuring resin purity.

The frequency of regeneration depends on various factors, such as water quality and treated water volume. The ability to reuse resins with a lifespan ranging from five to ten years reduces the environmental impact compared to the conventional approach.

Veolia: Your partner in ecological transformation

The environmental advantages of utilizing regenerated resins can be compared to a ripple effect, where the impact is amplified with each regeneration cycle. These benefits underscore the significant role that regenerated resins play in promoting sustainable water treatment practices.

Veolia Water Technologies prides itself on its expertise in water treatment and its commitment to partner stakeholders to bring about ecological transformation. Through the company’s Service Deionization offering, businesses can tap into advanced regeneration technologies to optimize the performance of their water treatment plants while minimizing environmental impact.

Veolia’s team of specialists meticulously assesses existing treatment processes and water quality before prescribing tailored regeneration solutions to address specific purity requirements and operational needs.

This approach not only reduces environmental impact by minimizing waste and maximizing resin lifecycles but also provides clients with peace of mind and significant cost savings. With Veolia’s comprehensive expertise in resin selection, system design, and ongoing maintenance, clients can be confident that their water treatment processes are in capable hands, allowing them to focus on their core business priorities.